Sand casting is a popular method of casting metal parts, where molten metal is poured into a mold made of sand to create a desired shape. This process is one of the oldest and most widely used metal casting techniques, dating back thousands of years.

Get a Free Quote Chat With UsSand casting is a popular method of casting metal parts, where molten metal is poured into a mold made of sand to create a desired shape. This process is one of the oldest and most widely used metal casting techniques, dating back thousands of years.

One of the key advantages of sand casting is its flexibility and cost-effectiveness. The materials required for sand casting are inexpensive and readily available, making it a cost-effective option for producing complex metal parts in large quantities. Additionally, sand casting allows for the creation of intricate shapes and designs that may be difficult or impossible to achieve with other casting methods.

The process of sand casting involves creating a mold by packing sand around a pattern of the desired part. The molten metal is then poured into the mold, where it solidifies and takes on the shape of the pattern. Once the metal has cooled and solidified, the sand mold is removed to reveal the final metal part.

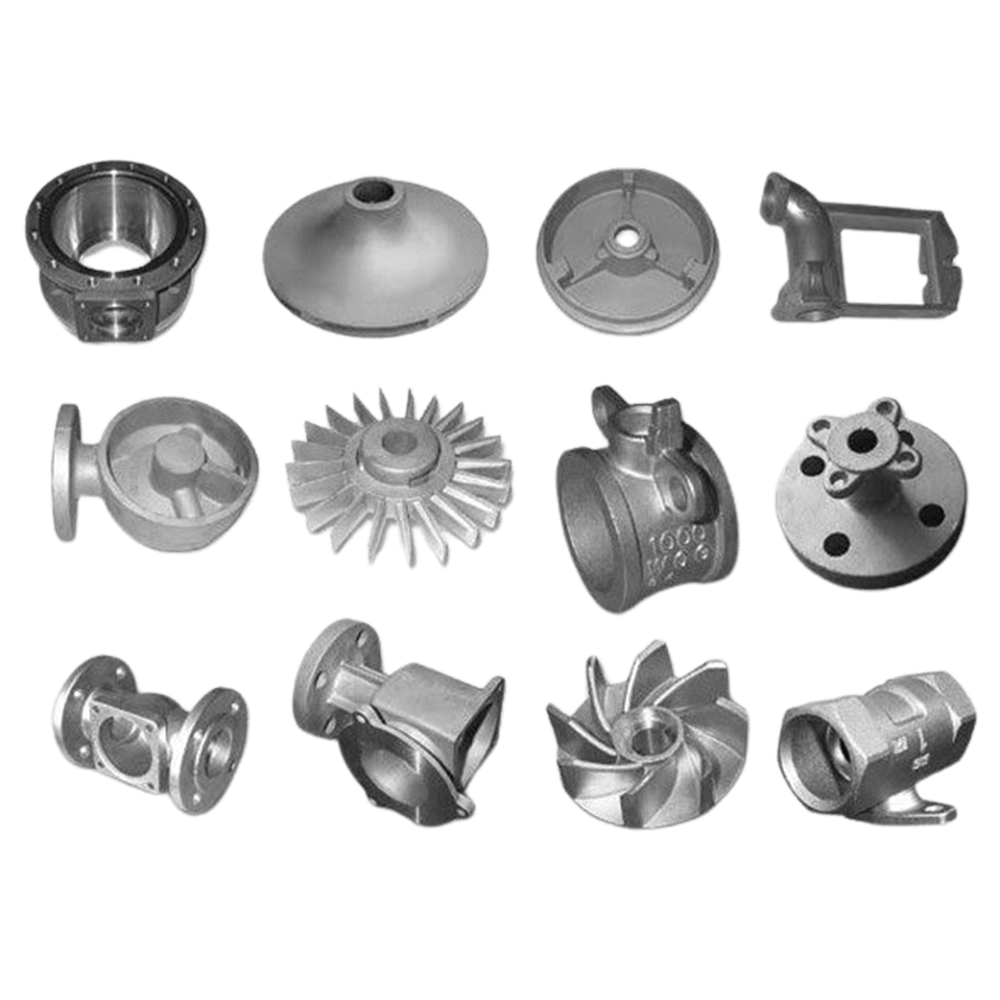

Sand casting is commonly used in the automotive, aerospace, and manufacturing industries to produce a wide range of parts, from engine components to industrial machinery. This method is ideal for creating large and heavy parts, as well as parts with complex geometries.

In conclusion, sand casting is a versatile and cost-effective method of casting metal parts that has been used for centuries. Its flexibility and ability to produce complex shapes make it a popular choice for a wide range of industries.