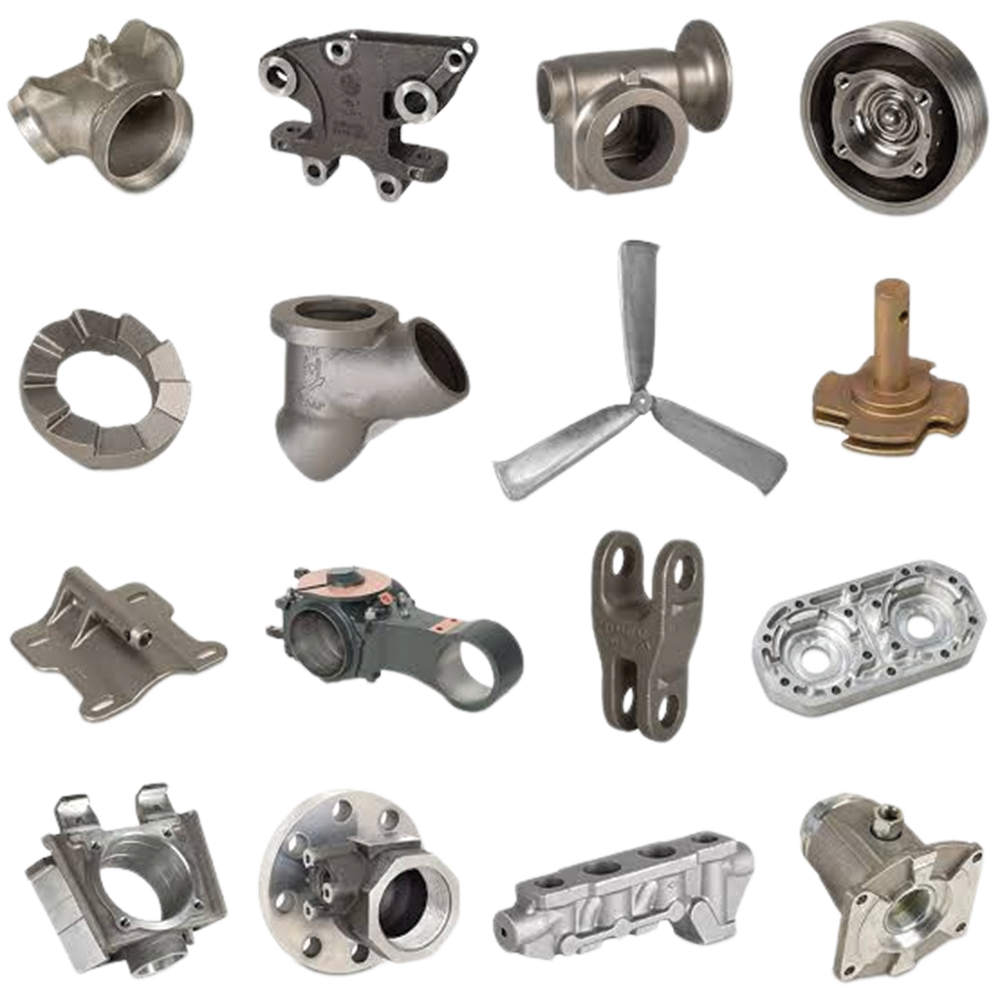

Forging is a manufacturing process in which metal is shaped by hammering, pressing, or rolling to create a desired shape or form. This process is used to create a wide range of products, from simple tools and utensils to complex machinery and structures. Forging is one of the oldest metalworking techniques, dating back thousands of years, and is still widely used today in industries such as aerospace, automotive, and construction.

Get a Free Quote Chat With Us

Forging is a manufacturing process in which metal is shaped by hammering, pressing, or rolling to create a desired shape or form. This process is used to create a wide range of products, from simple tools and utensils to complex machinery and structures. Forging is one of the oldest metalworking techniques, dating back thousands of years, and is still widely used today in industries such as aerospace, automotive, and construction.

There are several different methods of forging, each suited to different types of products and materials. The most common types of forging include open-die forging, closed-die forging, and seamless ring forging. In open-die forging, the metal is hammered or pressed into shape using dies that are open at the top, allowing the metal to flow freely. Closed-die forging, on the other hand, uses dies that completely enclose the metal, shaping it into a specific form. Seamless ring forging involves shaping a metal billet into a hollow ring shape using radial or axial compression.

Forging offers several advantages over other manufacturing processes, such as casting and machining. Forged parts are typically stronger and more durable than cast or machined parts, as the forging process helps align the grain structure of the metal, resulting in improved mechanical properties. Additionally, forged parts tend to have better fatigue resistance and impact strength, making them ideal for applications where reliability and performance are crucial.

In conclusion, forging is a versatile and efficient manufacturing process that is used to create a wide range of products with superior strength and durability. By carefully selecting the appropriate forging method and materials, manufacturers can produce high-quality components that meet the rigorous demands of modern industry.