Momai Technocast is ISO 9001:2013 certified.

Our Quality Assurance System covers all activities from design, development, production, installation, servicing and documentation. It introduced the sayings "fit for purpose" and "do it right the first time". It includes the regulation of the quality of raw materials, assemblies, products and components; services related to production; and management, production, and inspection processes.

Our Quality Policy emphasizes customer satisfaction, personal excellence and continual improvement. We are determined to offer the highest quality products and services that conform to International Quality Standards by making every individual responsible for Quality.

“It is our goal to deliver quality products, on time, at competitive prices. We will first arrive at a clear understanding of each customer’s requirements and then commit ourselves to fulfilling them exactly. We will achieve our stated goals by continuously improving our quality system to deliver a defect-free product.”

Impact Testing

- Charpy & Izod Impact Test upto 300J.

- Test Temp. -196 °C in conjunction with W10 Table 1, Note 10, with approval of TUV Nord.

Mechanical Testing

- Universal Testing Machine : Capacity 100 KN

- Electronic Extensometer for 0.2% Proof Stress.

Hardness Tester

- Measurement in Rockwell B and Rockwell C Scale.

- Range 0 to 100 Scale.

Chemical Analysis (Spectro Analysis)

- Fifth Generation SpectroMAXx-M, High End CCD Optical Emission Spectrometer with 5 Base (Fe+Ni+Co+Al+Cu) with 34 Elements from Spectro, GmbH.

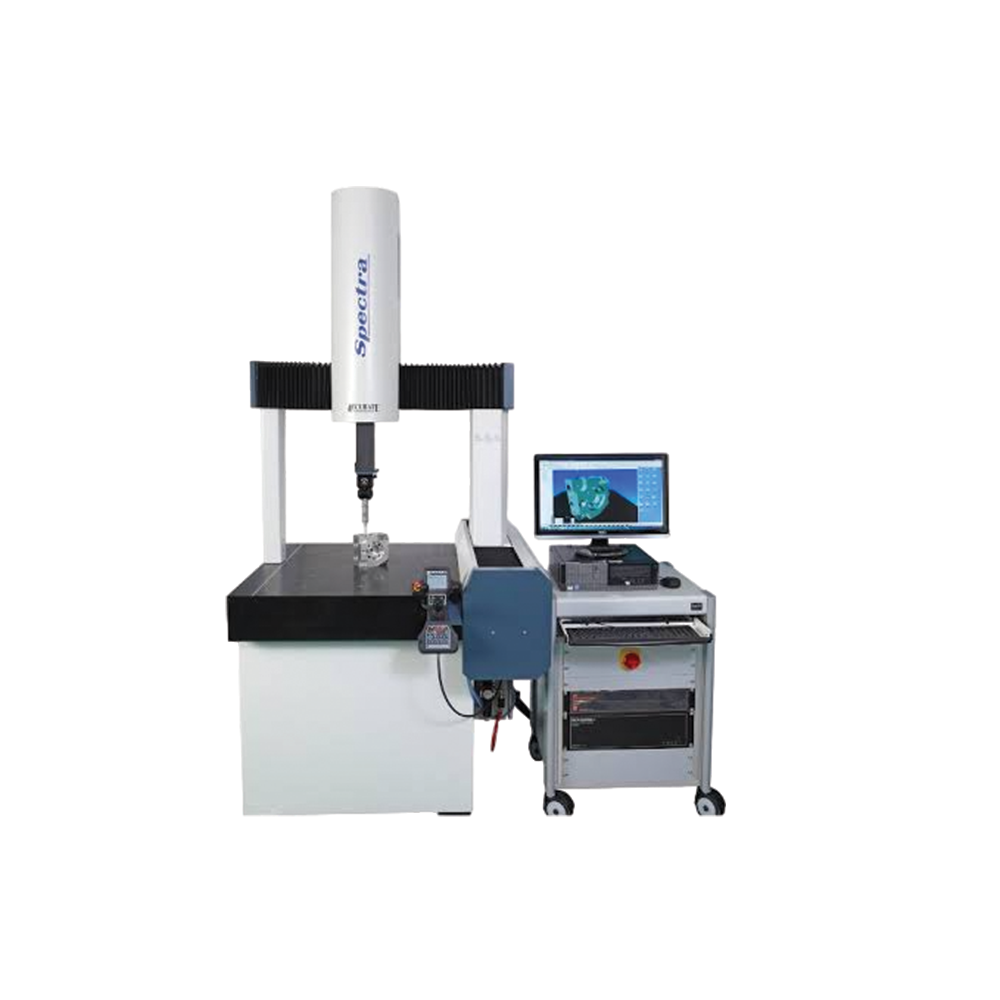

Coordinate Measuring Machine

- 3D CMM from Carl Zeiss

- Size: X=700, Y=700 & Z=600mm.

- Accuracy: 2.4 µm + L / 250.

Roughness Tester

- Measuring Range 0.03 µm to 6.35 µm

- Display Resolution 0.01 µm

2-D Height Gauge

- Range 0-600 mm

- Least Count 0.0005 mm

Radiation Measurement

- Digilert 100 (Mineralab LLC, USA)

Chemical Analysis

- In house spectrometer with 24 channels capable of testing Fe, Ni, Co, Al based materials and also Nitrogen content.

- All heats poured are tested on-line on Spectrometer.

- All the scrap used are also tested before using.

- Specimens are stored for particular period.

Physical Testing

- In house Universal Testing Machine.

- In house Hardness Testing Machine.

- In house Impact test Machine.

- In house metallurgical microscope.

- Specimens are stored for particular period.

Casting - Forgings Quality Control Check

- Surface defects are inspected with DP test & MPI Tests

- Internal casting defects are checked with RT Testing

- Visual Inspection as per SP 55 standard

- Surface finish check with reference standards

- Chemical Analysis

- Tensile Test - Impact Test

- Radiography (X-Ray)

- Dye Penetrate

- Corrosion Test

- Mechanical Porosity Test

- Microstructure

- Castings-Forgings can also supplied under third party inspections such as LLOYDS, BUREAU VERITAS and DNV etc